Why Do Jeans Have Those Tiny Buttons?

ADVERTISEMENT

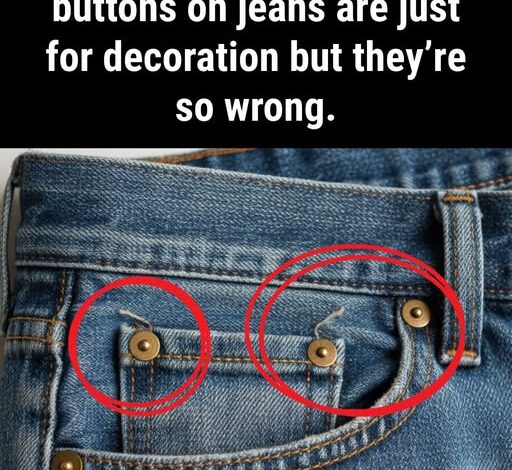

Most of us slip into jeans without a second thought, barely noticing the tiny metal studs near the pockets. Small, round, and often the same color as the rest of the hardware, they’re easy to overlook. To many, they seem like decorative touches—just another way brands make denim feel rugged or “authentic.” But those little dots aren’t just for show. They’re rivets, and without them, jeans wouldn’t have endured the wear and tear of their own legacy.

ADVERTISEMENT

🔩 The Rivet: Small Fix, Big Impact

A rivet is a simple metal fastener, hammered through layers of fabric to reinforce stress points—corners, seams, and pockets that take the brunt of daily use. Today, they’re part of the denim aesthetic. But in the 1870s, they were a solution born of necessity.

ADVERTISEMENT

Jeans back then weren’t fashion statements. They were survival gear for miners, railroad workers, and ranch hands. Denim was tough, but not invincible. Pockets tore, flies split, seams gave out. One tailor, Jacob Davis, kept hearing the same complaint: the pants didn’t last.

So he tried something new. He reinforced the weak spots with copper rivets—hardware borrowed from industrial use, not fashion. The result? Jeans that held up for months, even years. Davis saw the potential but lacked the funds to patent the idea. He partnered with his fabric supplier, Levi Strauss, and in 1873, they launched the riveted jean. It was built for function, not flair.

🛠️ From Workwear to Icon

Word spread fast. Workers loved the durability, and demand exploded. What started as a practical fix became a symbol of toughness. As denim shifted from workwear to everyday wear, rivets came along for the ride.

Technically, rivets are straightforward—usually made of copper or brass, metals that resist rust and handle stress. You’ll find them at the front-pocket corners, where strain builds from movement and weight. Older styles even had rivets near the fly and back pockets, though complaints from horseback riders (scratched saddles, torn leather) led manufacturers to hide or relocate them.

The genius of the rivet lies in how it distributes tension. Instead of fabric tearing at a single point, the rivet spreads the force, keeping the material intact. Anyone who’s owned jeans without rivets knows how quickly those corners fray.

🧵 Rivets in the Modern Era

Today, most of us aren’t hauling tools or laying track, but rivets remain. They’ve evolved from utility to badge—signals of “real denim” and a nod to Levi’s original design. Brands lean into this heritage, stamping logos into rivets, choosing contrasting metals, or arranging them in signature patterns.

Still, fashion has shifted. Some modern jeans skip rivets in favor of reinforced stitching or hidden fasteners. These designs offer cleaner lines and solve practical issues—like the discomfort of a rivet pressing into your hip during a long flight. Metal-free jeans also appeal to those seeking lightweight, recyclable clothing.

Yet denim purists swear by the old-school copper rivet. For them, it’s about more than durability. It’s about authenticity—wearing something built the way it was meant to be. Rivets connect today’s jeans to their roots, when clothing was judged by how long it lasted, not how it looked.

🧭 A Legacy in Every Stitch

As jeans age, their fabric softens and molds to the body, but stress points remain. Without rivets, those areas fray fast. With them, jeans hold together long enough to develop that beloved broken-in look. Even rivet placement tells a story—front pockets for strain, fly rivets for movement, back-pocket rivets hidden to avoid damage.

That quiet adaptability is why rivets have lasted 150 years. Trends come and go—skinny, wide-leg, raw, stretch—but rivets remain the invisible backbone of denim engineering.

When you pull on a pair of jeans, you’re wearing more than fabric. You’re wearing a piece of industrial history. Rivets are reminders of grit, invention, and the kind of work that demanded clothes built to last. They’re not decoration. They’re problem-solving made visible—a tiny detail with a massive legacy.